In the world of industrial finishing, powder coating has emerged as a versatile and efficient method for enhancing the durability, appearance, and overall performance of a wide range of products. It is a dry finishing process that has gained popularity due to its numerous advantages over traditional liquid paint applications.

In this article, we will explore the advantages of powder coating and delve into the reasons behind its widespread adoption in various industries.

12 Benefits of Powder Coating

1. Superior Durability

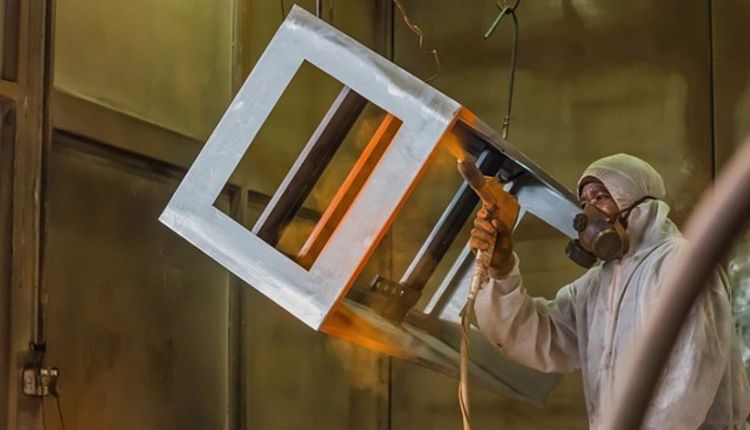

One of the foremost advantages of powder coating is its exceptional durability. The process involves applying a finely ground powder onto a substrate, which is then cured in an oven to form a protective film.

As a result, powder-coated products exhibit remarkable resistance to wear, corrosion, chipping, and cracking. This durability makes powder coating ideal for applications in harsh environments, such as automotive parts, outdoor furniture, and industrial machinery.

2. Aesthetically Pleasing Finishes

Powder coating offers an extensive range of color options and finishes, making it an excellent choice for those seeking durability and visual appeal. Whether you’re looking for a glossy, matte, textured, or metallic finish, powder coating can provide a consistent, high-quality appearance.

Powder coating also resists fading, chalking, and UV damage, ensuring your products maintain their aesthetic appeal over time. For industries that rely on the aesthetics of their products, powder coating is an attractive choice. Just make sure to opt for a reliable provider like Midwest Powder Coatings to ensure your finish is durable and long lasting.

3. Environmentally Friendly

The ecological impact of industrial processes is an increasingly critical consideration in today’s world. Powder coating stands out as an environmentally responsible finishing method. Unlike liquid paint, powder coating does not contain volatile organic compounds, which can lead to air pollution and have adverse health effects.

Furthermore, overspray from powder coating can be collected and reused, minimizing waste. The reduction in hazardous waste disposal makes powder coating a sustainable choice that aligns with environmental regulations and global efforts to reduce pollution.

4. Cost-Effective

The cost-effectiveness of powder coating can be attributed to several factors. First, the reduced waste associated with powder coating, as mentioned earlier, results in cost savings. Additionally, the durability of powder-coated products also leads to longer lifespans, reducing maintenance and replacement expenses.

Powder coating is highly efficient, with minimal material and energy wastage during the application and curing processes. This efficiency not only conserves resources but also reduces production costs.

5. Enhanced Uniformity

Achieving a consistent finish can be challenging with liquid paint, as it is susceptible to runs, sags, and other imperfections. Powder coating, on the other hand, offers exceptional uniformity and coverage.

The electrostatic application ensures that the powder adheres evenly to the entire surface, resulting in a smooth and flawless finish. This consistency is crucial for industries such as automotive manufacturing and appliances, where product appearance plays a significant role in customer satisfaction.

6. Quick and Efficient Application

The application process of powder coating is swift and efficient. The electrostatic attraction between the powder and the grounded substrate ensures that the powder adheres evenly and effectively. This reduces the need for multiple coats and touch-ups, as is often the case with liquid paint.

Furthermore, the curing process typically takes only a few minutes, allowing for rapid production turnaround times. Manufacturers can thus increase their productivity and meet demanding production schedules with ease.

7. Easy Maintenance

Maintaining powder-coated surfaces is straightforward. The durable finish is resistant to chipping, scratching, and fading, reducing the need for frequent touch-ups or repainting. Cleaning is also hassle-free, as the smooth surface can be easily wiped down with mild soaps and water.

This ease of maintenance is a significant benefit for both consumers and businesses, as it minimizes the time and cost associated with keeping products looking their best.

8. Excellent Adhesion

The electrostatic application process ensures strong adhesion of the powder to the substrate. This adhesion is further enhanced during the curing process, where the powder particles melt and bond to the surface.

The result is a coating that remains firmly attached and is less prone to delamination or peeling. This adhesion quality is especially important in applications where the substrate may experience mechanical stress or frequent handling.

9. Customization and Special Effects

Powder coating offers a wide range of customization options, making it possible to create unique and eye-catching finishes. Special effects, such as metallics, textures, and multicolor coatings, are easily achievable with powder coating.

This flexibility enables product designers and manufacturers to meet the market’s ever-evolving demands and create products that stand out from the competition.

10. Scratch Resistance

In environments where surfaces are subject to abrasion and frequent contact, the scratch resistance of powder-coated finishes is a notable advantage. Whether it’s the interior of an elevator, the frame of a bicycle, or the railing of a busy staircase, powder coating helps maintain the appearance of products despite the wear and tear they endure.

11. Recyclability

Powder coating is not only eco-friendly during the application process but also when it comes to disposal. Overspray from the coating process can be collected and reused, reducing waste and conserving resources.

Moreover, the overspray that cannot be collected can be safely disposed of without posing environmental hazards, as it doesn’t contain harmful solvents or VOCs.

12. Regulatory Compliance

Adhering to industry regulations and standards is a critical concern for manufacturers in various sectors. Powder coating often aligns well with regulatory requirements due to its eco-friendly and health-conscious attributes. Its absence of VOCs and hazardous chemicals makes it a preferred choice for industries subject to stringent environmental and safety regulations.

Finals words

In today’s industrial landscape, where durability, sustainability, and aesthetics are paramount, powder coating has risen as a superior finishing method that offers a multitude of benefits. Its remarkable durability, aesthetic versatility, eco-friendliness, and cost-effectiveness make it a smart choice for an extensive range of applications, from automotive parts to industrial elements.

Powder coating enhances the lifespan and performance of products and aligns with environmental regulations and safety standards, making it a sustainable and responsible choice for manufacturers. As the demand for durable, high-quality finishes continues to grow, the future of powder coating appears brighter than ever.